Mastering the Art of Welding: Exactly How to Avoid Undercut Welding Issues for Flawless Fabrication Results

Performance and accuracy are paramount worldwide of welding, where even the smallest blemish can jeopardize the architectural integrity of a fabricated piece. One typical difficulty that welders face is undercutting, an issue that can deteriorate a weld joint and lead to pricey rework. By recognizing the origin causes of undercut welding and carrying out effective strategies to avoid it, welders can elevate their craft to new levels of excellence (Preventing weld undercut). In the search of flawless construction outcomes, mastering the art of welding to avoid undercut problems is not just a skill however a necessity for those pursuing excellence in their work.

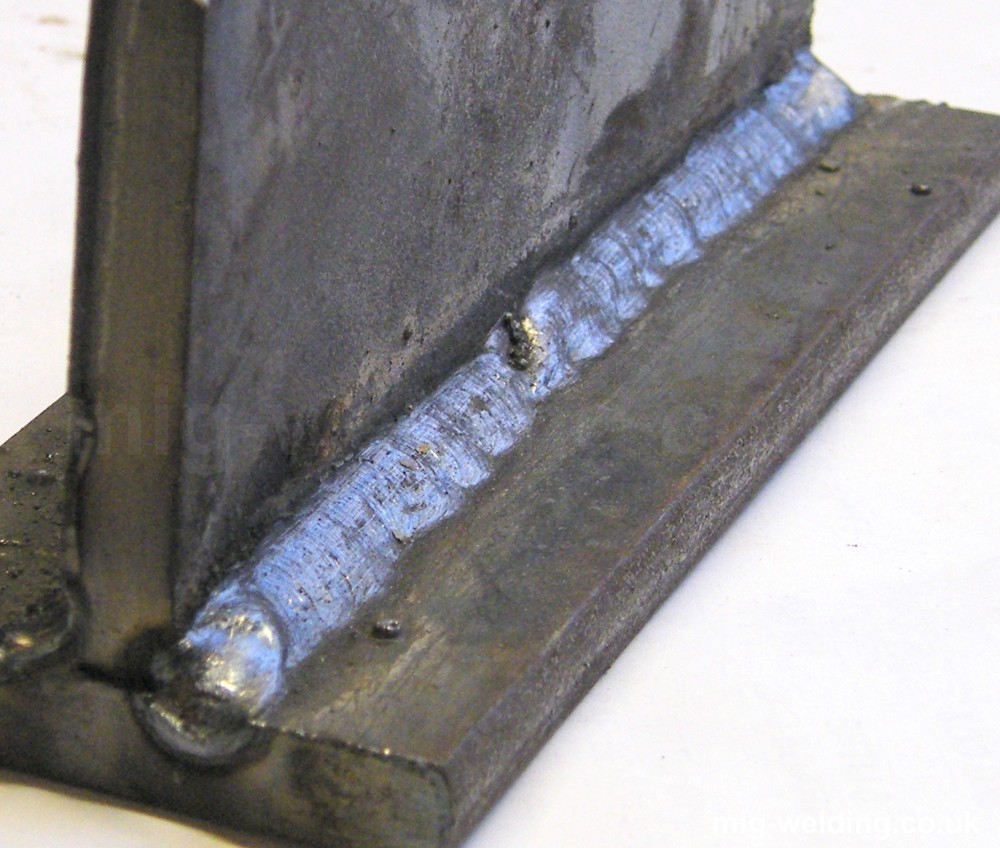

Comprehending Undercut Welding

To avoid undercut welding, welders ought to make certain proper welding criteria, such as changing the existing, voltage, travel rate, and maintaining the appropriate electrode angle. Additionally, utilizing the proper welding strategy for the specific joint configuration is vital. Utilizing weaving motions or backstepping techniques can assist make sure correct weld metal deposition and decrease the chance of undercut formation. Regular assessment of welds during and after the welding process is also crucial to capture any undercut early and make essential adjustments to avoid further problems. Preventing weld undercut. By comprehending the causes of undercut welding and carrying out preventive measures, welders can achieve top quality, structurally audio welds.

Root Causes Of Undercut in Welding

Understanding the variables that add to damage in welding is necessary for welders to produce premium, structurally sound welds. Insufficient welding current or wrong welding rate can likewise contribute to damage. Understanding these reasons and executing correct welding methods can help prevent damaging problems, ensuring long lasting and strong welds.

Strategies to stop Undercutting

To alleviate the danger of damaging in welding, welders can utilize calculated welding strategies targeted at enhancing the high quality and stability of the weld joints. One efficient approach is to change the welding criteria, such as voltage, existing, and travel rate, to make certain proper heat input and deposition. Preserving a suitable electrode angle and making certain constant travel rate can likewise aid stop undercut. In addition, making use of the correct welding strategy for the certain joint configuration, such as weave or stringer beads, can contribute to lowering undercutting. Preventing weld undercut.

Employing back-step welding methods and controlling the weld grain profile can likewise assist disperse warmth uniformly and lessen the threat of undercut. Regular inspection of the weld joint during and after welding, as well as implementing quality assurance measures, can aid in dealing with and discovering damaging issues without delay.

Value of Appropriate Welding Specifications

Picking and keeping proper welding specifications is essential for attaining successful welds with marginal problems. Welding parameters refer to variables such as voltage, existing, travel speed, electrode angle, and securing gas circulation price that straight affect the welding procedure. These parameters should be visit the site meticulously changed based upon the kind of material being welded, its thickness, and the welding strategy utilized.

Appropriate welding specifications ensure the correct amount of heat is related to thaw the base metals and filler product consistently. If the specifications are established also high, it can lead to excessive heat input, causing distortion, spatter, or burn-through. On the various other hand, if the parameters are also low, incomplete fusion, absence of infiltration, or damaging may take place.

Top Quality Assurance in Welding Operations

Verdict

To conclude, grasping the art of welding calls for he said a comprehensive understanding of undercut welding, its reasons, and methods to avoid it. By guaranteeing proper welding specifications and applying quality control methods, perfect construction results can be accomplished. It is vital for welders to regularly aim for excellence in their welding procedures to stay clear of undercut issues and generate top quality welds.

Undercut welding, a common flaw in welding processes, takes place when the weld metal does not appropriately fill up the groove and leaves a groove or depression along the bonded joint.To stop undercut welding, welders ought to ensure correct welding specifications, such as readjusting the current, voltage, traveling rate, and preserving the correct electrode angle. Inadequate welding current or wrong welding rate can also add to damage.To minimize the threat of damaging in welding, welders can utilize calculated welding methods intended at boosting the high quality and honesty of the weld joints.In verdict, understanding the art of welding requires a complete understanding of undercut welding, its causes, and techniques to prevent it.